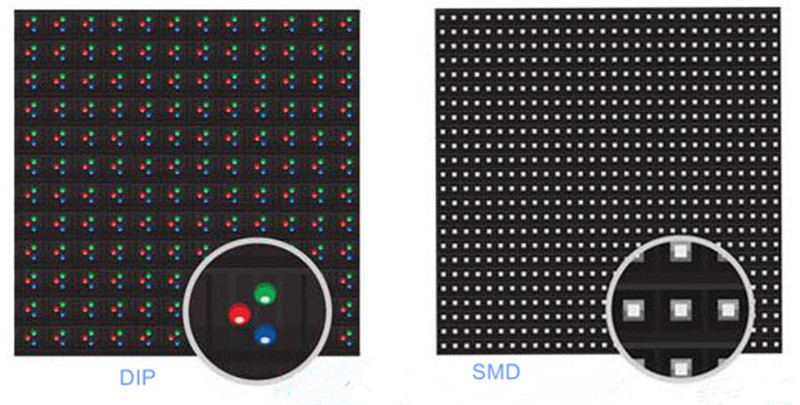

DIP

DIP is double in-line package, it was first developed. LED lamp beads are produced by the manufacturer, and then inserted by the LED module and LED display manufacturers on the LED PCB lamp board. After wave soldering, DIP semi-outdoor modules and outdoor waterproof modules are produced.However, due to the diameter of the lamp beads, currently only P6 can be achieved. Other P5, P4 or even higher density outdoor LED displays cannot be made. However, the protection performance of in-line is good, but the viewing angle is not accurate and fixed, generally between 100-110, and high energy consumption, not environmentally friendly, so it is only suitable for outdoor, currently there is a large market in outdoor P10-P20 Share.Moreover, it adopts DIP packaging to produce, the process is complicated, it is not easy to mechanize production, and the production efficiency is low. In addition, there are many DIP manufacturers, there is no high technology and equipment threshold, and the competition is fierce. Many manufacturers use inferior raw materials and PCB boards to reduce costs to fight for market share. The quality is low and there is almost no perfect after-sales guarantee.

SMD

SMD is surface mounted device,generally mounted components are leadless or short-lead surface-mounted components, which need to be printed with solder paste on the circuit board, then mounted by a chip mounter, and then fixed by reflow soldering. The DIP welding is a direct-in-package packaged device, which is fixed by wave soldering or manual soldering.

The products of SMD chip components are generally automatically mounted by the whole machine, and the defect rate is very low. In contrast, the performance of DIP package products cannot be compared with SMD components

The main advantages of SMD components are as follows:

- High assembly density, small size and light weight of electronic products, the volume and weight of SMD components are only about 1/10 of traditional plug-in components

- High reliability and strong anti-vibration ability. Low solder joint defect rate.

- Good high frequency characteristics. Reduced electromagnetic and radio frequency interference.

- Fully automated production with stable quality.

The main disadvantages of SMD are as follows:

COB

COB is chips on board,mainly solve the heat dissipation problem.Compared with SMD and DIP,it’s main character is save space.

Disadvantages:

- Poor consistency: Because there is no step to select lamps, it can not be separated and separated, and the consistency is poor.

- Serious modularity: Because it is composed of many small unit boards, the color is inconsistent and the modularity is serious.

- Surface flatness: Because it is a single lamp dispensing, the flatness is poor, and the graininess is obvious to the touch.

- Difficulty of maintenance: Due to the need for professional equipment, maintenance is difficult and the cost of maintenance is high. Generally, it is returned to the factory for maintenance.

- Manufacturing cost: Due to the high defect rate, the manufacturing cost is far higher than the small pitch of SMD.

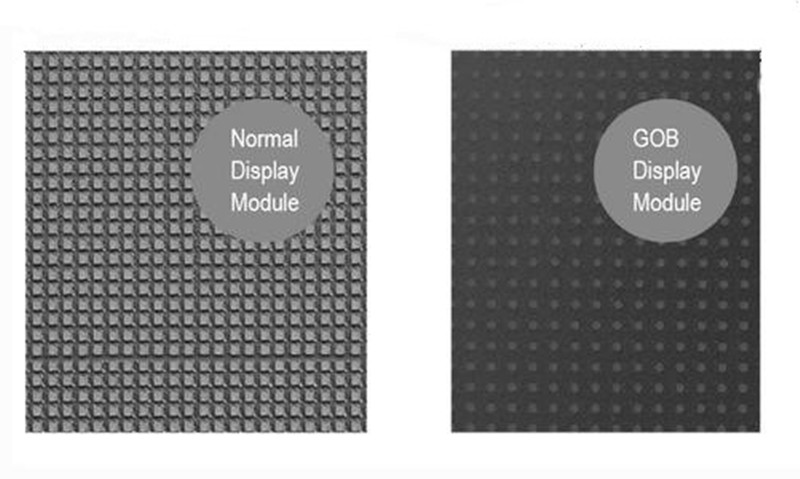

GOB

GOB is glue on board

It is a technology to solve the problem of LED lamp protection.An advanced new transparent material encapsulates the substrate and its LED unit board to form effective protection. This material not only has super high transparency Ming performance, while also possessing super thermal conductivity. The GOB small pitch can be adapted to any harsh environment, realizing the characteristics of moisture-proof, waterproof, dust-proof, impact-proof, UV-resistant and so on.Its characteristics are: high protection, moisture-proof, waterproof, anti-collision, anti-UV, can be applied to more harsh environments, avoid large-scale dead lights, light off and other phenomena.

Compared with COB, its features are simpler maintenance, lower maintenance cost, larger viewing angle, and horizontal and vertical viewing angles can reach 180 degrees. It can solve the problem that COB cannot mix lights, serious modularity, poor spectral separation, poor surface flatness, etc problem.For more information about Flinky LED display, please follow us on Twitter,Linkedin,Facebook,Instagram,Pinterest,Tumblr and so on!